In collaboration with Josh Waldman

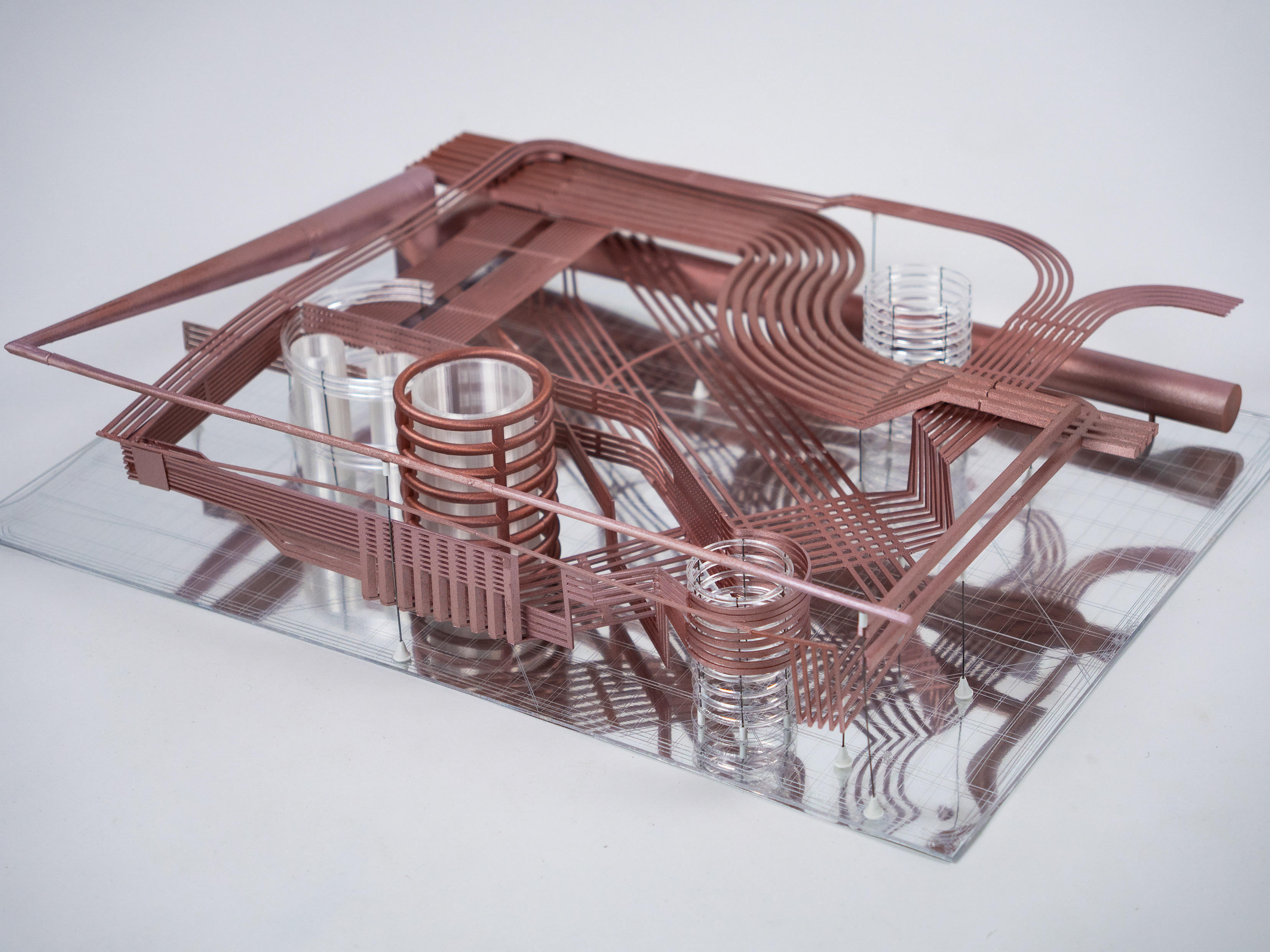

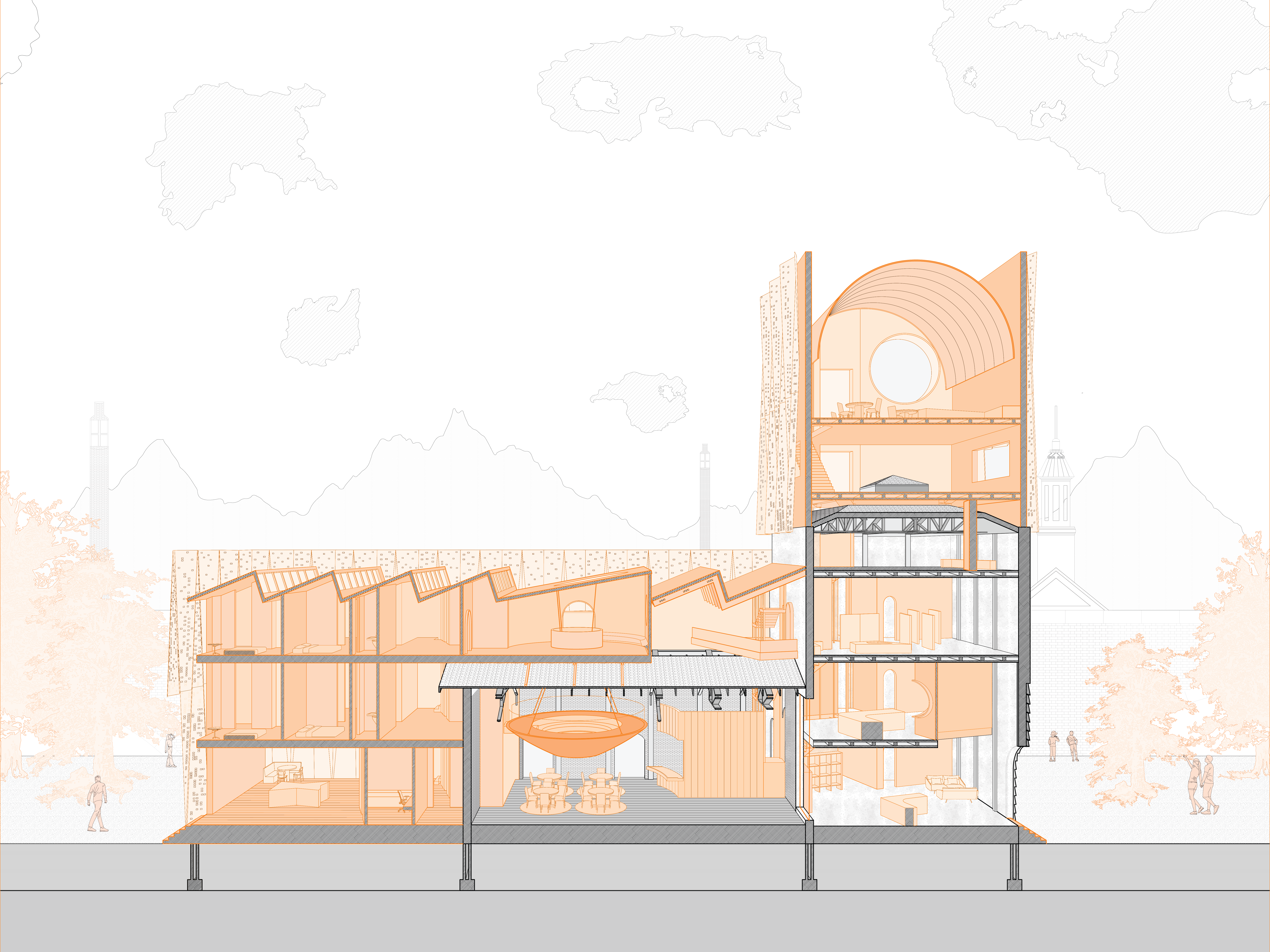

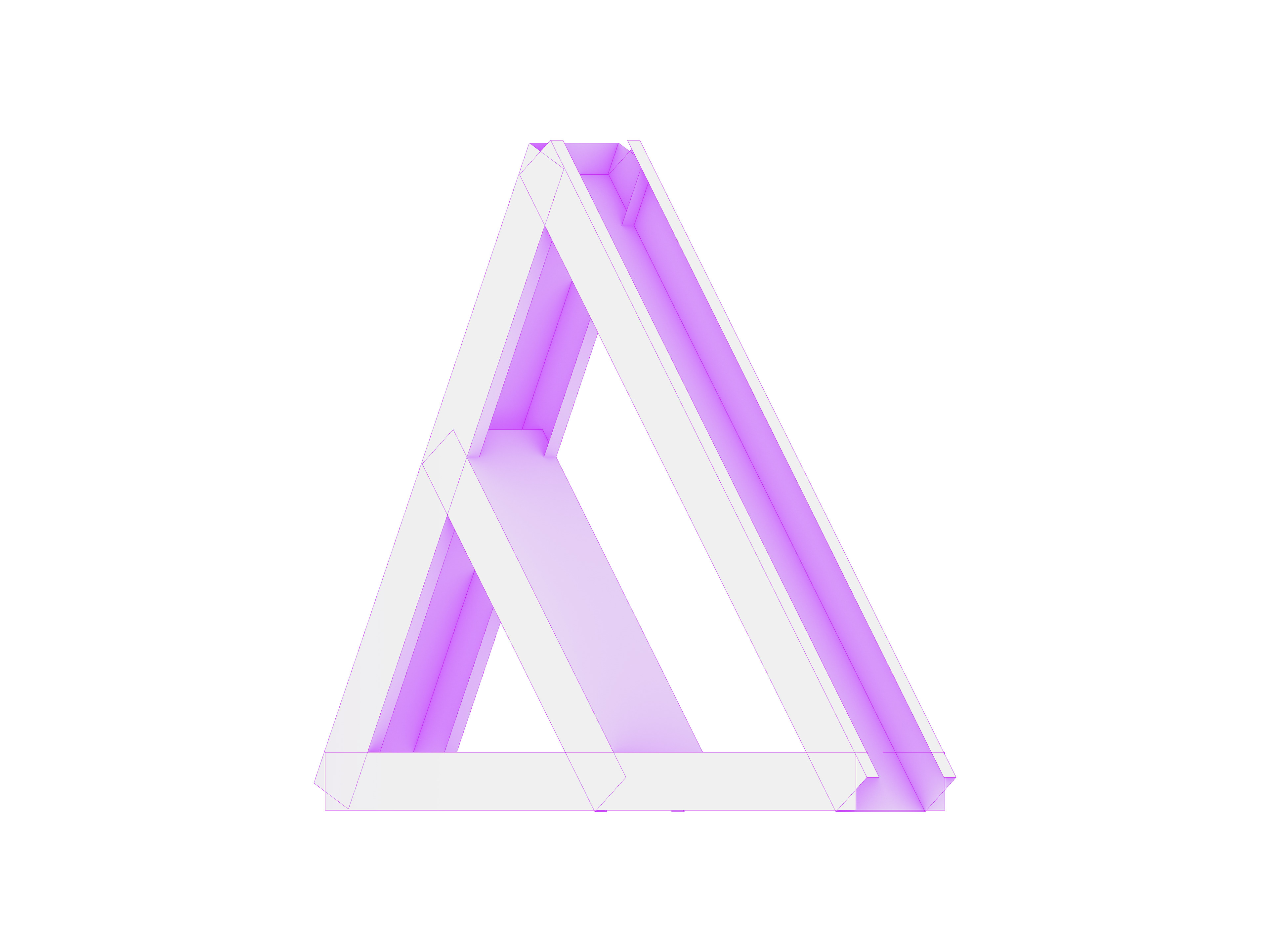

Using stud.io’s revolutionary technology, a full-scale, parametric, metal stud system was developed and assembled, calling into question the role of computation in contemporary design practice as digital fabrication is often critiqued as not being scalable and applicable to larger projects since it is primarily used for highly specialized prototyping and installations. However, by using robotically fabricated steel studs that can be easily assembled into almost any form, the project, and class, demonstrates prefabrication’s ability to be applied to a myriad of architectural contexts.

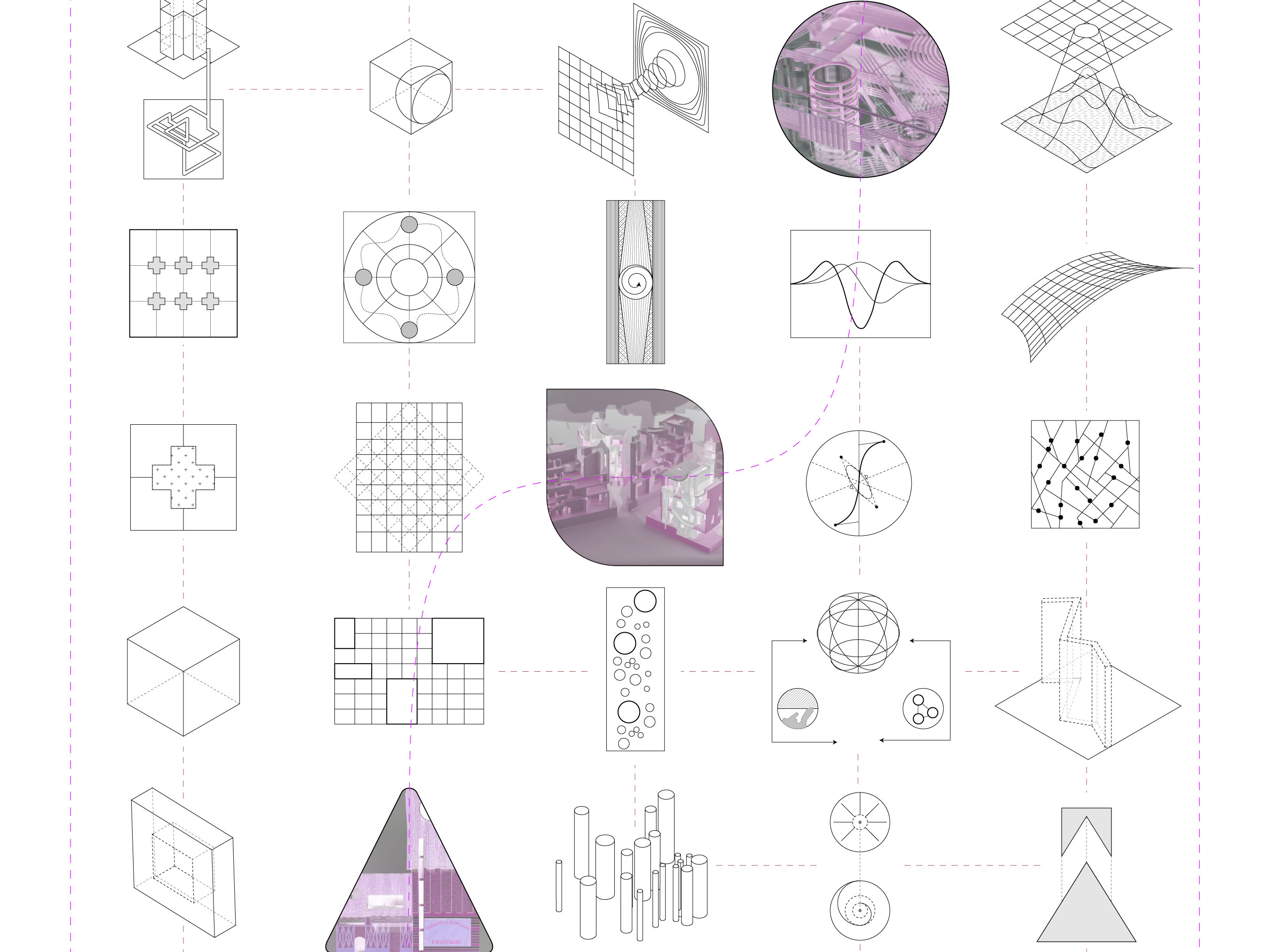

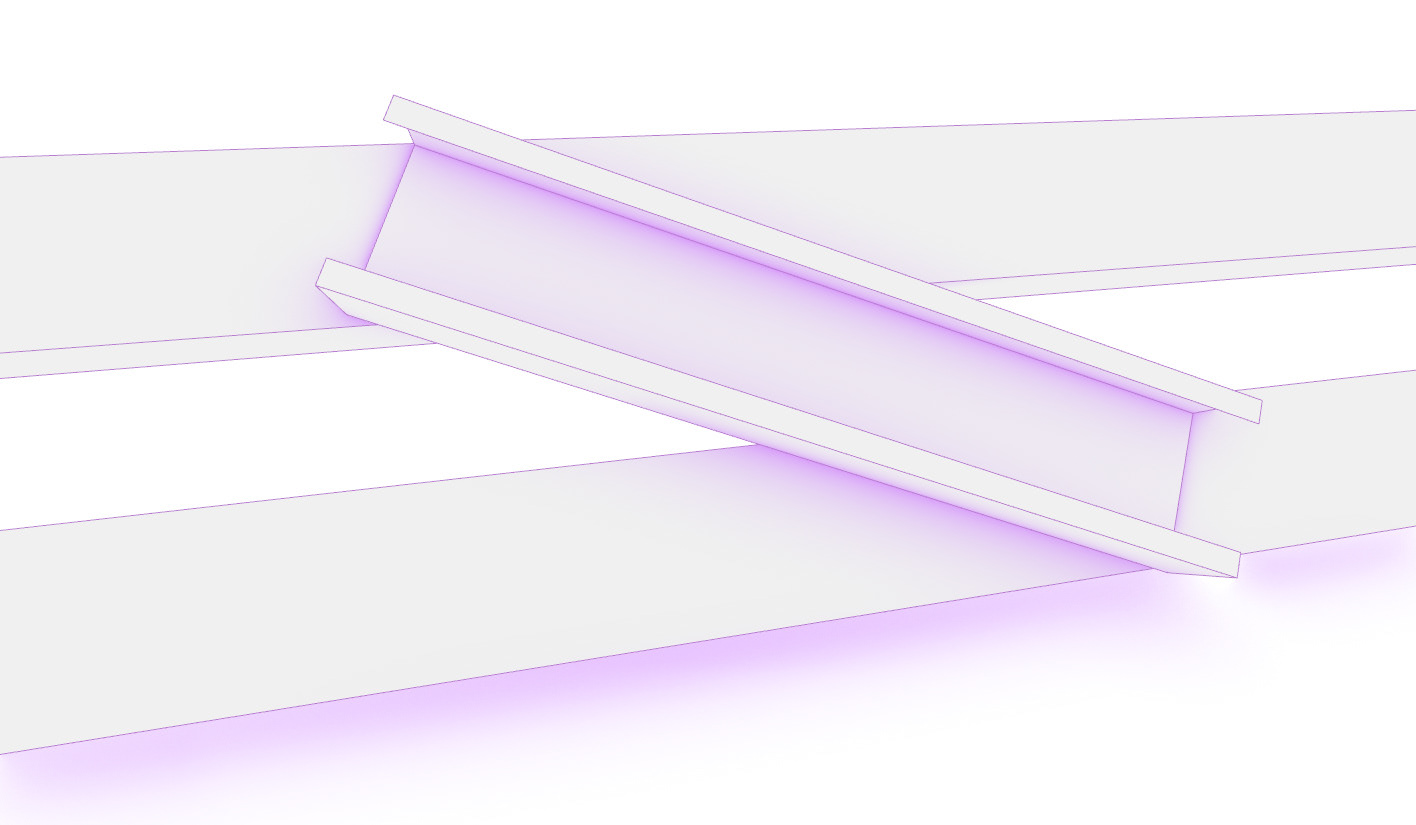

Connection Type 1

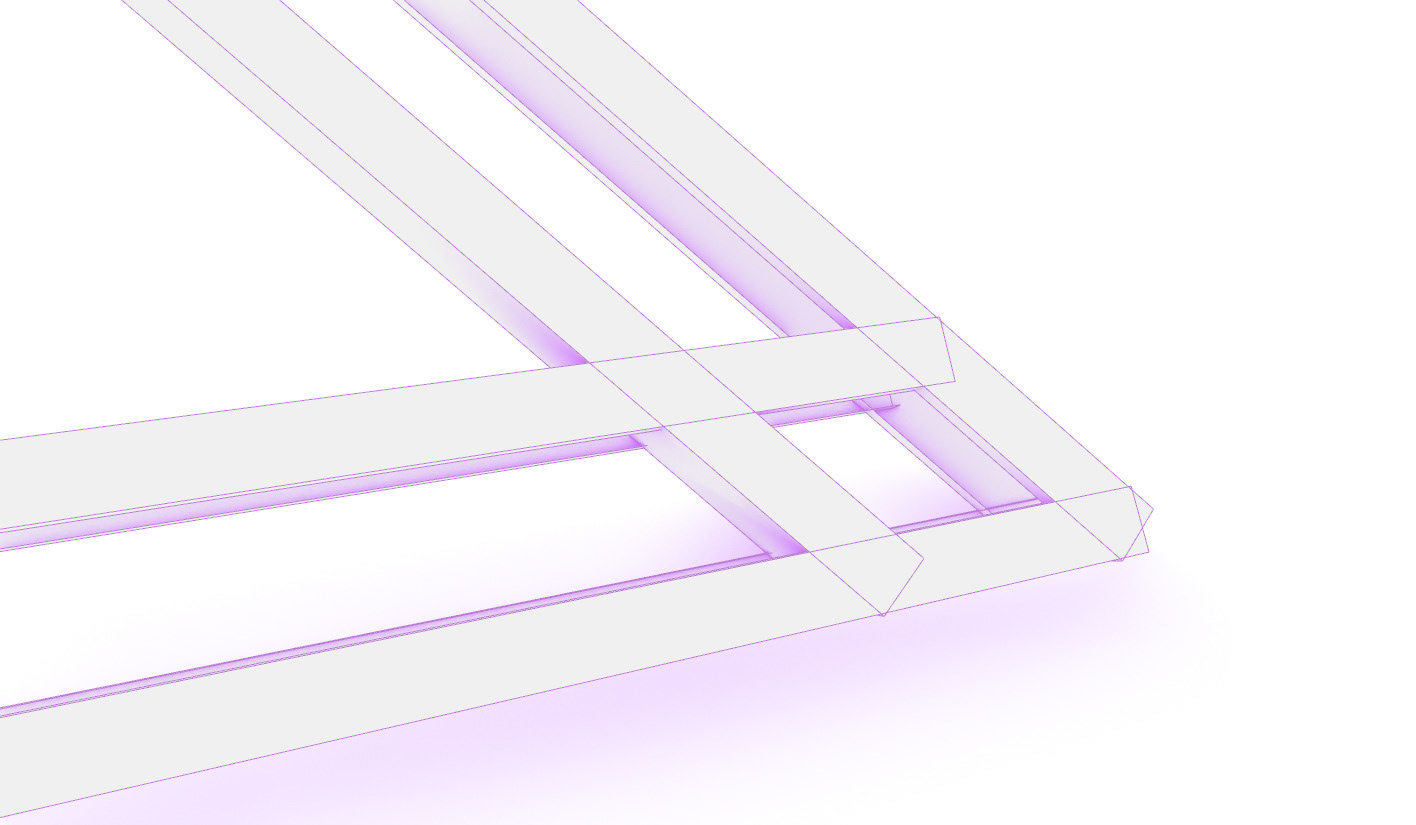

Connection Type 2

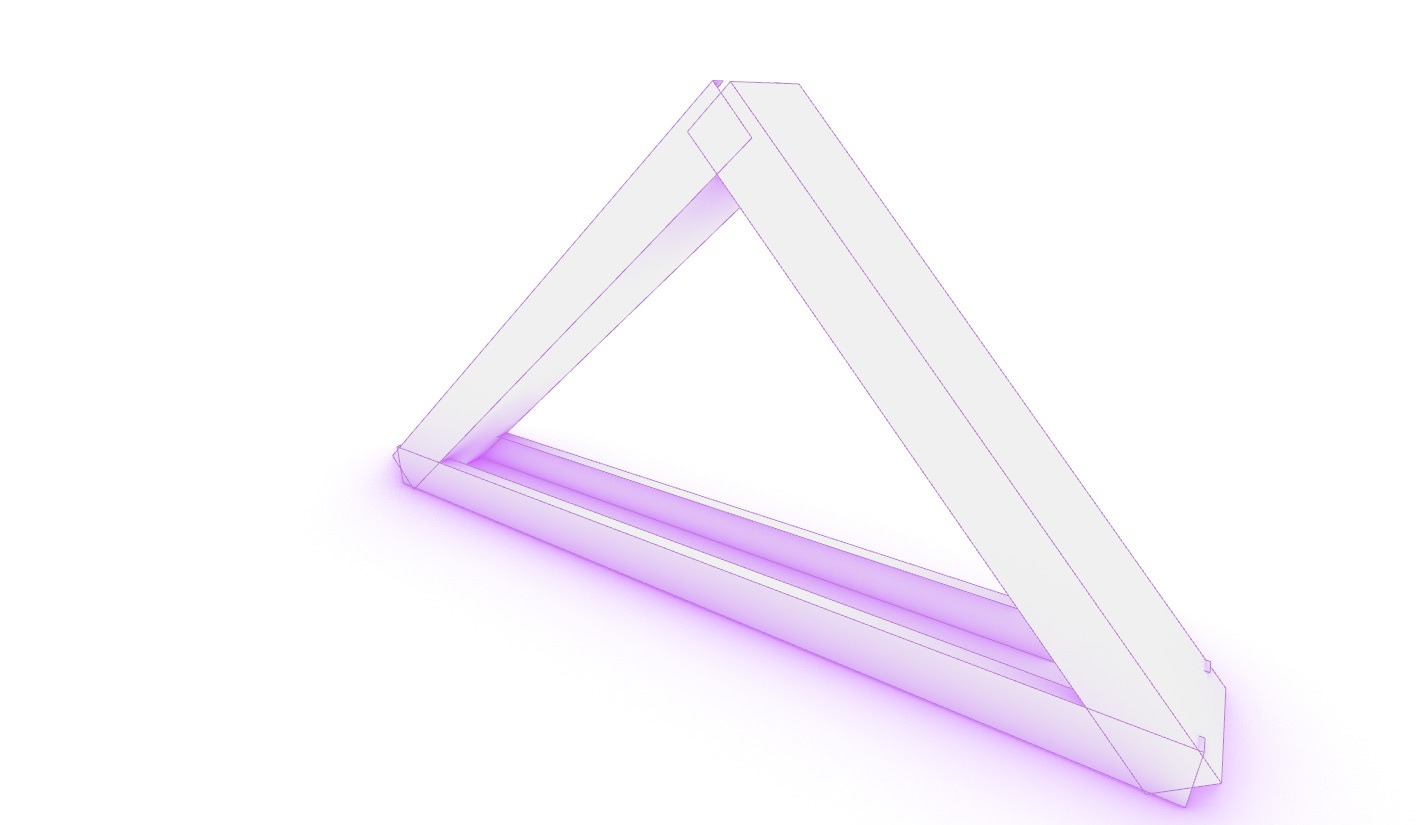

Connection Type 3

Connection Type 4

Every Component is Customized and Labeled Before Being Fabricated in L.A.

Studs that connect web to web (back to back) must have webs that lie on the same plane. Similarly, the center axis of studs that connect by slotting into one another must also lie on the same plane. These constants resulted in the use of 4 key connection types.

The project developed from the unfolding and hinging of the fragmented legs of a cube, which naturally overlap and bend, yielding spatial constraints for the rigid, triangular structure: the bottom planes of the first and last legs must lie perpendicular to the ground and the central axis of each triangular face must also lie on the same plane. The project then became a study of corner conditions and resolving planar geometry in an effort for a seamless structure that flows along one, continuous line. The form invites engagement - a loose enclosure space that pushes the bounds of structural capacity by reaching the maximum possible overhang angle.